HACCP Plans for Small-Batch Producers

Understanding HACCP: The Basics for Small-Batch Producers

Hazard Analysis and Critical Control Points (HACCP) is a systematic approach to food safety that identifies, evaluates, and controls hazards throughout the food production process. For small-batch producers, implementing a HACCP plan can seem daunting, but it is essential for ensuring the safety and quality of your products. The process begins with understanding the seven principles of HACCP: conducting a hazard analysis, determining critical control points, establishing critical limits, monitoring procedures, corrective actions, verification procedures, and record-keeping.

Small-batch producers often face unique challenges, such as limited resources and fluctuating production volumes. However, these challenges can be addressed by tailoring the HACCP plan to fit the specific needs of your operation. For instance, simplifying documentation and focusing on the most critical hazards can make the process more manageable. By understanding the basics of HACCP, small-batch producers can lay a strong foundation for a robust food safety system.

Identifying Hazards: A Critical Step for Small-Batch Producers

Identifying potential hazards is the cornerstone of any HACCP plan. For small-batch producers, this step involves a thorough analysis of all stages of production, from raw material sourcing to packaging and distribution. Common hazards include biological (e.g., bacteria, viruses), chemical (e.g., pesticides, allergens), and physical (e.g., metal fragments, glass) contaminants.

To effectively identify hazards, small-batch producers should consider factors such as the nature of the ingredients, processing methods, and storage conditions. Engaging with food safety experts or using industry guidelines can also provide valuable insights. Once hazards are identified, they must be evaluated based on their severity and likelihood of occurrence. This risk assessment helps prioritize which hazards require control measures, ensuring that resources are allocated effectively to mitigate the most significant risks.

Establishing Critical Control Points: Tailoring for Small Batches

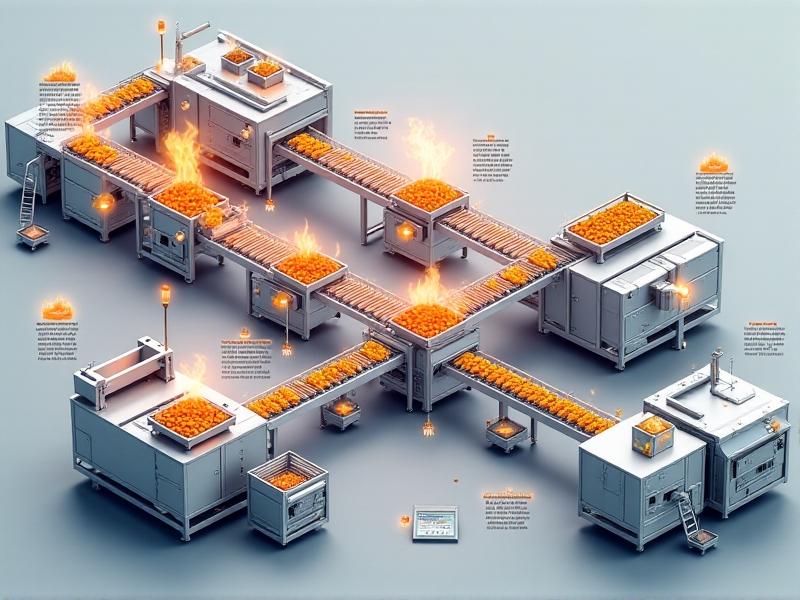

Critical Control Points (CCPs) are stages in the production process where control measures can be applied to prevent, eliminate, or reduce hazards to acceptable levels. For small-batch producers, establishing CCPs requires a careful balance between thoroughness and practicality. Given the smaller scale of operations, it may be feasible to implement more stringent controls without overburdening the process.

Examples of CCPs include cooking, cooling, and packaging stages, where specific measures such as temperature control or metal detection can be applied. It is crucial to document the rationale for selecting each CCP and to establish critical limits that define the acceptable range for each control measure. These limits should be based on scientific evidence or regulatory requirements to ensure they are effective in mitigating the identified hazards.

Monitoring and Verification: Ensuring Compliance in Small-Batch Production

Monitoring is the continuous observation of CCPs to ensure that critical limits are being met. For small-batch producers, this can involve simple yet effective methods such as manual temperature checks or visual inspections. Regular monitoring not only helps in maintaining food safety but also provides valuable data for verifying the effectiveness of the HACCP plan.

Verification involves reviewing records, conducting audits, and testing products to confirm that the HACCP plan is functioning as intended. Small-batch producers can benefit from periodic internal audits and third-party inspections to gain an objective assessment of their food safety practices. By consistently monitoring and verifying CCPs, producers can build confidence in their HACCP plan and demonstrate their commitment to food safety.

Record-Keeping: Simplifying Documentation for Small-Batch Producers

Record-keeping is a vital component of a HACCP plan, providing evidence that control measures are being implemented effectively. For small-batch producers, maintaining detailed records can be challenging due to limited administrative resources. However, simplifying the documentation process can make it more manageable without compromising on quality.

Essential records include hazard analysis, CCP monitoring results, corrective actions, and verification activities. Using digital tools or templates can streamline the record-keeping process, making it easier to track and review data. Accurate and organized records not only support compliance with regulatory requirements but also serve as a valuable resource for continuous improvement in food safety practices.

Training and Culture: Building a Food Safety Mindset in Small Teams

Training is essential for ensuring that all team members understand and adhere to the HACCP plan. For small-batch producers, fostering a culture of food safety within the team can have a significant impact on the success of the plan. This involves not only providing initial training but also offering ongoing education and reinforcement of food safety principles.

Creating a food safety mindset requires leadership commitment and clear communication. Encouraging team members to take ownership of their roles in the HACCP plan can lead to greater accountability and vigilance. Regular team meetings and open discussions about food safety challenges can also help in identifying areas for improvement and reinforcing best practices.

Continuous Improvement: Adapting HACCP Plans for Evolving Needs

The food industry is constantly evolving, and so are the challenges associated with food safety. For small-batch producers, continuous improvement is key to maintaining an effective HACCP plan. This involves regularly reviewing and updating the plan to address new hazards, changes in production processes, or updates in regulatory requirements.

Feedback from team members, customers, and audits can provide valuable insights for improvement. Additionally, staying informed about industry trends and advancements in food safety technology can help small-batch producers stay ahead of potential risks. By adopting a proactive approach to continuous improvement, producers can ensure that their HACCP plan remains robust and responsive to the dynamic nature of food production.